RUDHOLM GROUP

PACKAGING & LABELING - MADE IN THE USA

Rudholm Group USA wants to make a difference and not only offer USA Made products but manufacture them with its focus on sustainable practices with the least impact on the environment and has nearshored its production facilities into the United States for a fully Made in USA product.

Our third and newest location in the US has opened in Las Vegas, Nevada. Here we print, convert, and distribute Water Activated Paper Packing Tape, Recycled LDPE polybags and Recycled LDPE Polymailers which are custom printed with high performance water-based or UV ink. This new facility is a 18,000 square ft manufacturing plant & warehouse with machines specially equipped for custom digital- and flexo printing on film-based plastics.

Rudholm Group’s Los Angeles print hub prints & converts GRS certified recycled polyester satin & nylon taffeta labels, as well UPC stickers that are printed on recycled paper. We strive with quick turnaround times of 72 hours or less, depending on order qty, product and raw material availability. Our print facility is 10 minutes away from Downtown LA and shipments are done locally, or with Fedex Overnight service across the US.

RUDHOLM GROUP

FLEXIBLE PACKAGING – MADE IN LAS VEGAS

Flexo Printed Recycled LDPE Poly Mailers

Flexographic printed poly mailers are the best choice for larger production runs with MOQ of 20,000 plus.

Print plates are required and customized water-based inks will be used to meet your customized specifications.

Product Information:

- 3-Layer Recycled LDPE Film

- Standard thickness: 75 micron/2.95 MIL

- Latest water-based ink technology

- Single or Double adhesive closure with perforation for easy returns

- Up to 4-colors; print plates with fees required

Digitally Printed Recycled LDPE Poly Mailers

Digitally printed poly mailers are fully customizable with no color limitations and full print coverage from edge to edge available.

This is a great option for low MOQ runs of 250 plus with fast turnaround time.

Product Information:

- 3-Layer Recycled LDPE Film

- Standard thickness: 75 microns/2.95 MIL

- Greenguard Certified UV Ink

- Single or Double adhesive closure with perforation for easy returns

- Full CMYK color spectrum; no print plates required

Flexo Printed Recycled LDPE Polybags

Flexographic printed polybags are customizable or standard RHG branded polybags with suffocation warnings are available.

Product Information:

- Monolayer Clear Recycled LDPE film

- Standard thickness: 40 microns/1.55 MIL

- Latest water-based ink technology

- Resealable & permanent adhesive closure options

- Up to 4-color print; print plates with fees required

BDP® BIODEGRADABLE TECHNOLOGY

Our US made polybags and poly mailers can be recycled and if they end up in landfills, they will naturally decompose within a few years with the use of our BDP® Biodegradable additive. Intertek ASTM D5511 testing is available upon request.

FAST SHIPPING

Get our fully in the US made polymailers and polybags within just a few weeks after order confirmation and artwork approval.

ECO-FRIENDLY

Our mailers & polybags are made with recycled LDPE and printed with water based inks.

MADE IN USA

Our poly mailers are 100% made in USA

RUDHOLM GROUP

CORRUGATED BOXES - MADE IN LOS ANGELES

We offer personalized corrugated boxes with custom prints, all proudly “Made in USA” and crafted from recycled paper, championing quality and sustainability. Whether it’s vibrant CMYK digital prints or the timeless allure of 3-color Flexo printing, your vision guides us.

CUSTOM MAILER BOX

The Roll End Tuck Top (RETT) box is a popular mailer style – chic, robust, and primed for seamless mailing. This versatile box shines in any shade and suits various needs: from apparel and gift boxes to subscription packages and beyond. Mailer boxes come in various form, 32 ECT, C Flute , E-Flute, 1/16″ or B-Flute 1/8″ single-wall corrugated cardboard and can ship between 1-30 lbs. Our team of experts will provide you with the best material option based on your product and shipping needs.

KRAFT

When envisioning a classic box, our minds often turn to the natural brown corrugated cardboard. This material not only captures an eco-conscious essence but also complements darker hues impeccably, offering an understated and unpretentious aesthetic for any parcel. Additionally, Kraft material boasts the highest recycled content among all materials, solidifying its position as the epitome of eco-friendliness.

WHITE

Our foundational white corrugated cardboard is the go-to economical choice for tailor-made branded boxes. Its matte white finish serves as a reliable backdrop, perfectly highlighting colors, logos, text, and design nuances while still being an eco-friendly option.

STANDARD RSC CORRUGATED BOX

Protection is the name of the game here and corrugated custom shipping boxes are the star player. These regular-slotted-containers (RSC) are the most economical choice for shipping bulkier items. They’re thick, strong, and secure without skimping on style. We use an industry-standard 32 ECT, C Flute that is made with 100% recycled paper and offer the same in white or natural kraft base.

WHITE

A favorite choice, our timeless white cardboard boasts an exquisite matte texture and complements all colors, especially vivid, vibrant shades.

KRAFT

Durable and attention-grabbing, our personalized kraft cardboard boxes feature a brown exterior and interior. Complementing rich tones, this natural finish adds an organic touch.

HIGH QUALITY & FAST DELIVERY

RECYCLABLE & RECYCLED

TWO-SIDED PRINTING

DIGITAL CMYK & FLEXO PRINTING

RUDHOLM GROUP

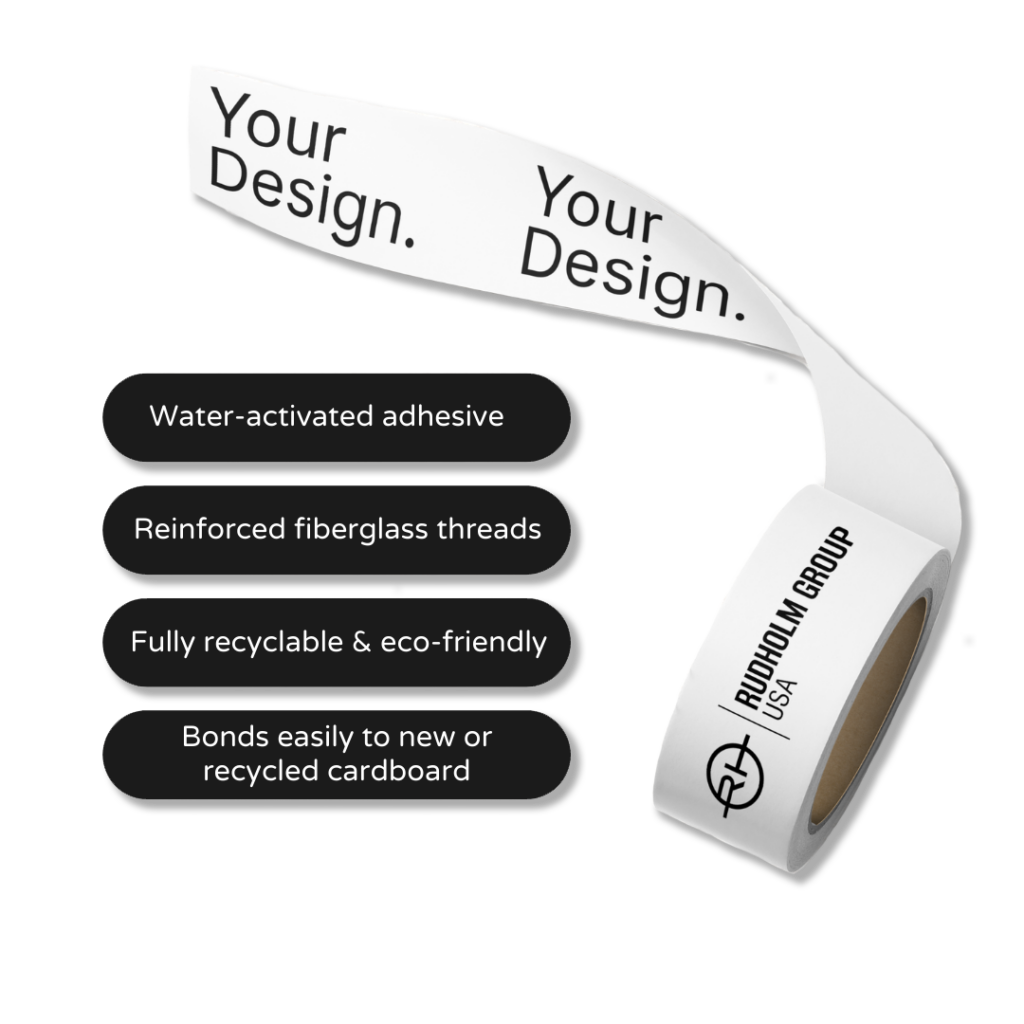

CUSTOM PACKAGING TAPE - MADE IN LAS VEGAS

Our kraft paper tape is made in the US and fully recyclable, allowing you to proudly advertise your brand without compromising sustainability. Its reinforced fiberglass threads improve package security, while its water-activated adhesive easily bonds to cardboard and dusty surfaces.

Choose from a natural Kraft or white base tape

Print up to 4 ink colors

Stock prints available upon request

Available in Regular, Medium and Heavy duty strength

Can be used with any water-activated Kraft-tape dispenser

RUDHOLM GROUP

CARE-LABELS & VARIABLE DATA STICKERS - MADE IN LOS ANGELES

The print hub of Rudholm Group located in Los Angeles specializes in printing and converting labels made from GRS certified recycled polyester satin and nylon taffeta, as well as UPC stickers that are printed on recycled paper. Our goal is to provide quick turnaround times of 72 hours or less, depending on the order quantity, product, and availability of raw materials. Our facility is conveniently located just 10 minutes away from Downtown LA, and we offer local shipments or FedEx overnight service across the US. RHG USA is dedicated to producing environmentally friendly products and processes, and we proudly maintain our annual certification by the GRS Standard.

• GRS Certified Recycled Polyester Satin

• GRS Certified Nylon Taffeta Tear-away

• UPC Stickers

• Color Stickers

• Low MOQ’s and fast turnaround times

RUDHOLM GROUP

OUR SUSTAINABILITY PROMISE

Rudholm Group stays on top of sustainable innovations and remains dedicated to ensuring traceability of products and meet high environmental, social, and anti-corruption standards all while delivering quality products.

In early 2020, our Los Angeles hub received the GRS (Global Recycled Standard) certification for all its recycled polyester satin and nylon taffeta labels produced in the US. This international, voluntary product standard mandates third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions.

Rudholm Group in Las Vegas has partnered with a North American Sustaianbility company, Change Plastic For Good® who have a patented biotechnology that addresses plastic’s end of life. It is proven through robust data and is tested by Intertek based on the ASTMD5511, ASTM D5988 and ASTM D6691 standards.

The organic BDP® polymer is added to our recycled LDPE during the blow film extrusion process and accelerates natural decomposition if our bags escape recycling streams and end up in landfill or our environment. What used to take centuries, now takes a few years to naturally decompose as BDP® attracts microbes to consume the plastic.

BDP® treated plastics have been tested via the ASTM D5511, ASTM D5988& ASTM D6691, ASTM D5388 in which accelerated biodegradation has been determined by microbial action. The digested plastics have been tested via OECD 207 & 208 by Intertek to show no microplastics or toxins remain after digestion. *Actual biodegradation rates will vary in biologically active landfills according to the type of plastic used, the product configuration, and the solid content, temperature, and moisture levels of the landfill.

Furthermore, Rudholm Group USA has championed the WeCare® – Circular Program to change the face of post-e-commerce throughout the United States. This program allows apparel brands to collect and return poly bags and poly mailers from customer returns at distribution centers and retail stores. Rudholm Group USA then collects these materials, recycles them, and creates a new product out of the resins. In doing this, Rudholm Group USA is working hand-in-hand with customers to create a circular economy for the betterment of people and the planet.

RUDHOLM GROUP

YOUR LOCAL GLOBAL COMPANY

NEW YORK

RHG USA, LLC – 89 5th Avenue,

Suite 801 New York,

NY 10003

LOS ANGELES

RHG USA, LLC – 5450 Bandini Blvd,

Suite B, Bell, CA 90201 Los Angeles,

CA 90058

LAS VEGAS

RHG USA, LLC – 1065 American Pacific Drive, Suite A/100

Henderson, NV 89074